- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why does embroidery lace still set the tone for modern womenswear?

2025-11-11

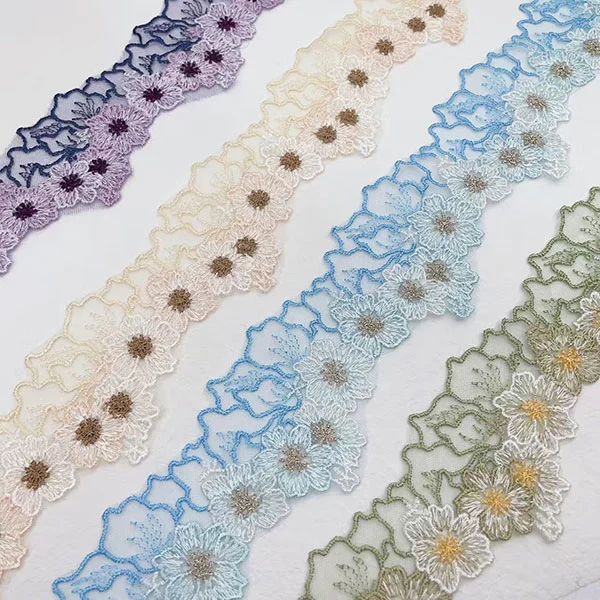

I design trims for everyday dresses and evening pieces, and time after time I watch the right Embroidery Lace pull an outfit into focus. At L&B, my days run between computer-guided embroidery lines and an in-house dye room, so a sketch can become a stitched motif before lunch and a dyed sample before dinner. That pace matters when a client needs elegance that feels lived-in rather than staged.

What do I really mean when I say embroidery lace for daily wear and for night looks?

It is the stitched artwork itself—motifs, scallops, and negative space—rather than a generic trim. I use lace as a visible design decision: sew-on collars for knit tops, appliqués that halo a neckline, hem lace that lands just below the knee so the pattern reads as a shadow. The same language works for evening, only with longer repeats, finer stitches, and subtler sheen.

How do water-soluble embroidered collars change a dress without changing the pattern?

Water-soluble bases let me embroider a collar or yoke as a free-standing piece that is rinsed clean of its support, leaving only the thread structure. I can upgrade a stock dress block in minutes—hand-tack the collar, top-stitch if needed, and the silhouette feels custom. This approach is friendly to small runs and quick refreshes between seasons.

Which fiber should I choose for my lace and why does the choice matter?

I reach for different yarns depending on drape, color depth, and care. Here is the short list I share with buyers when we sample materials for collars, trims, and appliqués.

| Material | Hand feel and drape | Color and dye notes | Strength and care | Best use cases | Price band | Extra notes |

|---|---|---|---|---|---|---|

| Milk silk blend | Soft with a fluid fall that flatters curved collars | Takes dye evenly with gentle luster | Good everyday durability with cool touch | Sew-on collars, T-shirt yokes, lingerie accents | Mid | Comfortable against skin for neckline trims |

| Polyester | Springy body that holds crisp motifs | Excellent colorfastness and shade stability | Wrinkle-resistant and easy care | Occasion hems, strong scallops, uniform repeats | Entry to mid | Great for bulk programs and tight timelines |

| Cotton | Matte hand with breathable comfort | Warm, natural shades with vintage mood | Softens with wash and ages gracefully | Day dresses, casual shirting, heirloom looks | Mid to premium | Pairs well with denim, poplin, and linen blends |

How do we keep color consistent from lab dip to bulk delivery?

- I start with a target fabric swatch from the garment body rather than a Pantone alone, then run three lab dips that bracket the target so you can judge in real light.

- Our dye techs record temperatures, time, and water hardness for repeatability across lots.

- We test rub fastness and wash fastness before releasing bulk cones to the embroidery floor.

What production checks protect stitch integrity and clean cut edges?

- Thread and needle pairing is set per pattern density to avoid puckering on tight satin stitches.

- Frame tension is calibrated so motifs stay true at high stitch counts.

- Jump threads are trimmed and edges are heat-sealed or taped depending on fiber.

- Final pieces are pressed over forms to set curvature for collars and cuffs.

Can small labels start with modest quantities and still request custom artwork?

Yes. I keep a rolling library of fresh motifs—more than twenty new ideas move through sampling every week—so you can pick a base design and tweak scale, edge profile, or filler stitch. If you have a logo or sketch, we digitize and embroider a proof, then price the program transparently so a capsule drop feels realistic.

Where do sew-on trims and collars make the biggest visual difference?

- Necklines that need structure without a facing.

- Hems where a scallop can replace a turned edge.

- Waist seams to break up solids on day dresses.

- Sleeve openings for a light bell effect without adding volume.

Which problems do buyers run into when ordering lace and how do I avoid them?

- Motif scale looks perfect on paper but reads too small on body, so I pin paper cutouts on a fit model before I stitch the first sample.

- Shade variance appears under store lighting, so I evaluate lab dips under daylight, warm retail light, and cool warehouse light.

- Seam allowances get crowded by lace near zippers, so I mark keep-out zones on tech packs for stress points.

What does a realistic sample to ship timeline look like?

- Artwork and digitizing in two to three days with an approval photo.

- First stitched sample and lab dips inside one week for most fibers.

- Bulk embroidery, dyeing, and finishing in one to three weeks depending on quantity and color count.

Why do I trust an integrated embroidery floor and dye room for daily orders?

Our computerized machines stitch repeatable results, the dye team keeps color true, and the finishing crew trims and presses to spec. That flow meets daily order needs without trading away detail, which is how elegance survives in real production life.

How can we talk about your dress line and build the right lace today?

If you have a mood board or a garment sample, send it over and I will propose stitch density, fiber, and edge type that fit your target price and care plan. I welcome custom concepts and small runs for testing a market, and I keep proven patterns for volume programs when your styles scale.

Would you like samples or a quick quote?

Tell me your garment fabric, target shade, and quantity, and I will prepare options with lead times and costs. If you are ready to move or want to see collars and trims in hand, please contact us with your style reference and delivery window. I reply with swatch ideas, photos, and a clear path from sample to bulk so your lace looks as good on hanger as it does in your head.